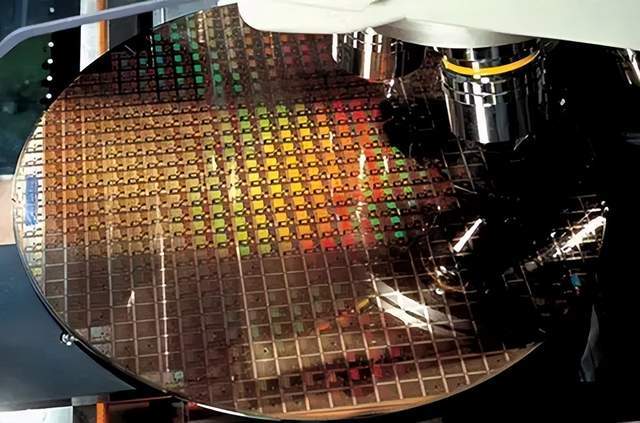

It was officially confirmed that the influence of chip cutting in the United States appeared, and TSMC also followed the highest cut of 50%

Delivery time:

2022-11-12 16:52

Source: Sina.com

The Economic Daily in Taiwan, China, China, quoted the industry chain news that TSMC had officially reduced its production capacity, so it cut orders on a large scale. The industry chain enterprises providing services for TSMC were cut orders by up to 50%, indicating that TSMC was finally forced to follow suit with the reduction of orders for American chips.

TSMC was first hit by the fact that 3nm was not mass produced due to lack of customers. Originally, Intel and Apple had booked TSMC's 3nm process capacity, but Intel gave up because the GPU chip was delayed for one year. Apple finally chose a more mature 4nm process for its A16 processor because the performance parameters of the 3nm process were not up to standard and the cost was too high. As a result, TSMC's 3nm process lost customers.

Secondly, Qualcomm, AMD, NVIDIA, etc. cut orders. After the peak production period of Apple's A-series processors passed, these chip companies would quickly fill Apple's gap and ensure TSMC's capacity utilization. However, Qualcomm's frustration in the high-end chip market led to its lack of confidence in Snapdragon 8G2, while AMD and NVIDIA were forced to reduce orders due to declining performance, resulting in TSMC's 5nm (including N4 process) The capacity utilization rate of 7nm process decreased.

The third is the recession of the global chip industry. The global chip oversupply has emerged since the beginning of this year. In the second half of this year, this situation finally affected the chip foundry enterprises of TSMC. In addition to the above chip enterprises, other chip enterprises also cut orders in the second half of this year, which led to a serious overcapacity of TSMC's advanced process capacity.

The Taiwan media pointed out that the industry chain had received instructions from TSMC to reduce the purchase volume in September, which showed that the introduction of TSMC had already shown signs of insufficient demand after the completion of the A16 processor stock, and it cut orders by 40% to 50%, highlighting that the introduction of advanced industrial overcapacity of TSMC was much more serious than expected.

After TSMC has established its leading edge in technology from the 16nm FinFET process in the past 10 years, it has been relying on the leading edge of advanced technology to capture the largest share of the chip foundry market, accounting for more than 50% of the chip foundry market. However, TSMC has now faced multiple difficulties.

In terms of advanced process research and development, TSMC's 3nm process research and development progress was not smooth, which led to repeated delays in mass production time, and ultimately almost missed the mass production time of Apple's A16 processor. However, Apple later found that the 3nm process was far from meeting the expected performance requirements after testing, highlighting the increased difficulty of advanced process research and development.

By contrast, Samsung, which also developed the 3nm process, is one step ahead of TSMC. Samsung is the first to introduce the surround gate technology in the 3nm process, while TSMC still uses the FinFET process. As a result, Samsung is ahead of TSMC in the 3nm process. Unfortunately, Samsung has not found customers, which shows that the cost of advanced processes is leading to a lack of interest in chip enterprises.

Another major blow to TSMC is its largest customer group - American chip. Since the first half of the year, the news of high inventory of American chip has been continuously spread, and in the second half of the year, it finally decided to reduce orders. American chips contributed nearly 70% of TSMC's revenue, and their order reduction led to a sharp decline in the utilization rate of TSMC's county-level process capacity.

The Taiwan media quoted the information of the industry chain that TSMC's orders to the industry chain were declining in the fourth quarter of this year and the first quarter of next year, and the decline was far greater than expected. The order reduction was up to 50%, indicating that the reduction of advanced processes was very large. At the same time, Taiwan media also reported that TSMC executives had asked their employees to take more holidays, and it was unpaid holidays, highlighting that in order to reduce costs, TSMC not only closed the EUV lithography machine, but also hoped to reduce labor costs.

TSMC seems to have reached a turning point. In addition to the above cost saving measures, it has also reduced its capital expenditure next year, which is expected to reduce by up to $4 billion, highlighting the impact of the global chip market entering the cold winter. At this time, the order reduction of American chips is even worse. With many adverse news coming out, TSMC's share price is continuing to decline, and its market value has halved since this year, It seems that this trend will lead to further decline.